What is lubricant?

Automotive lubricants are specialized substances designed to reduce friction, heat, and wear out between moving parts within automotive engines and other mechanical systems. These lubricants play a crucial role in ensuring the efficient and smooth operation of various components in vehicles, such as engines, transmissions, differentials, and steering systems. They are formulated to provide lubrication, reduce frictional losses, and protect metal surfaces from corrosion and premature wear.

How many types of lubricants have?

Lubricants are usually oil-based, plastic, solid, or sometimes a combination of these. The most common type of lubricant is usually oil or grease, but there are other types that we may encounter. It’s important to understand the different lubricants and their distinct functions.

Here are the types of lubricants that one must surely know.

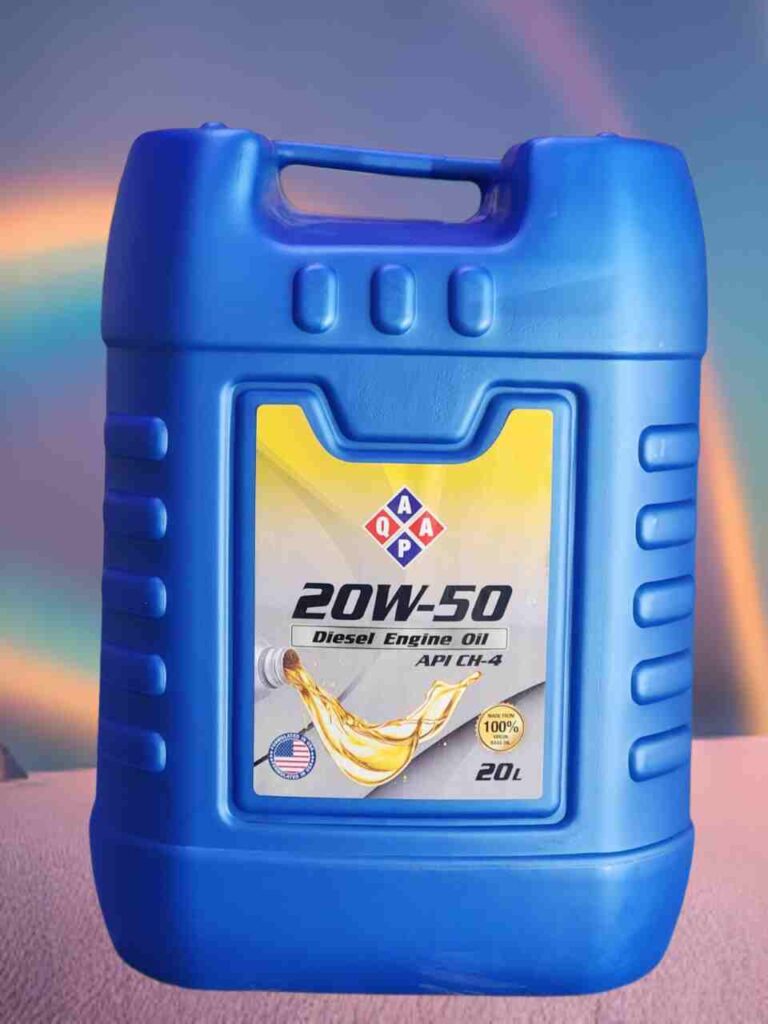

1. Engine oil – Engine oil is the most common type and also one of the most crucial automotive lubricants. Engine oil is responsible for the complete lubrication of the combustion chambers of the engine by reducing the friction of moving parts. A key role played by the engine oil is maintaining viscosity even at higher running temperatures. Engine oils usually contain several different additives such as dispersants, detergents, and anti-wear additives to increase the life of the engine components. Manufacturers often suggest changing the engine oil at regular intervals.

2. Gear Oil: Gear oils are mainly used for manual transmissions, transmission boxes, and differentials in vehicles. They usually have very high viscosity and contain extreme pressure additives containing phosphorus sulfur compounds to cope with the high-pressure movements. The Gear oil does not need to be changed as often as engine oil but has a much longer life and is often changed after 100,000 km.

3. Greases: Greases could be made from petroleum or synthetic products, thickener, and additional additives. It is similar to oil but its thickness makes it ideal for the lubrication of gears, bearings, and linkages. Some of the newer high-performance lubricants such as synthetic greases that are made of silicone have been successfully used in high mechanical pressure situations such as torque transmissions.

4. Penetration Lubricants: These are highly refined, flowy fluids meaning they are a low viscosity oil. They are usually in aerosol-type containers. They are being used on stubborn and rusted nuts and bolts. They are most effective when they are sprayed and are allowed to soak in. Penetration lubricants wear very fast and often need frequent reapplication.

5. Dry Lubricants: They are an easy-to-use, mess-free form of lubrication. They are made of liquids such as water, alcohol, and dry lubricating particles. They usually come in an aerosol spray canister. Once sprayed the liquid evaporates and leaves behind a layer of dry lubrication. They are best used for smaller parts such as hinges and threaded rods that otherwise would get stuck with grease.